Four point probe

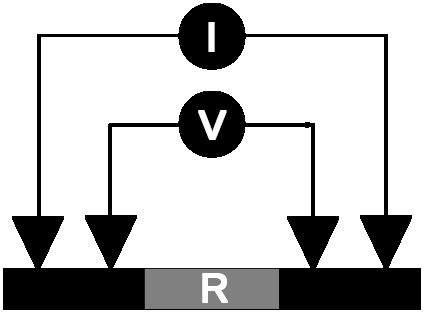

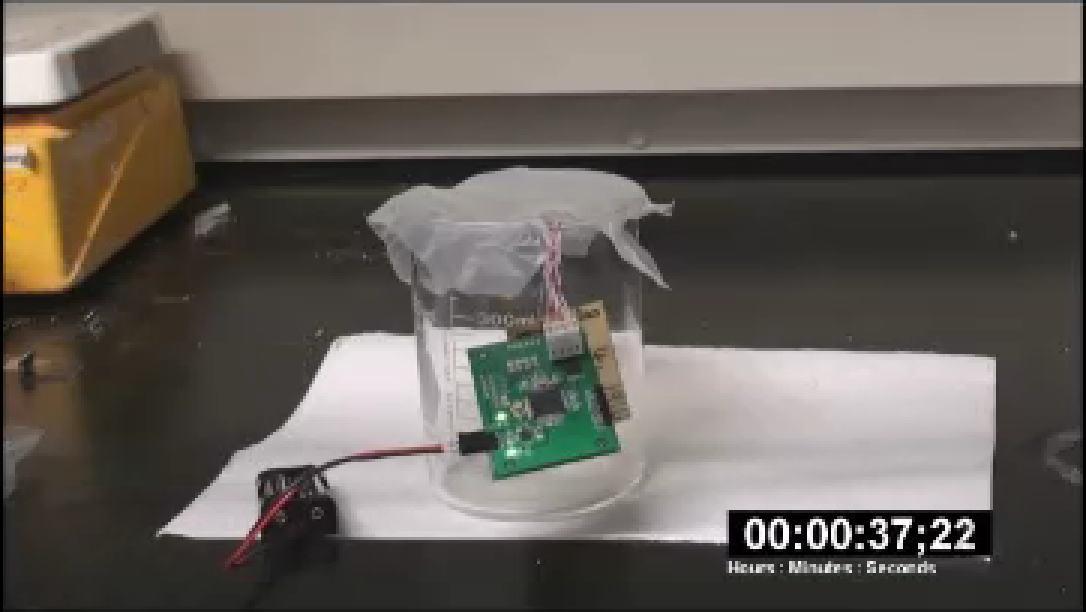

While researching resistive type Graphene sensors, I needed to demonstrate their portability. I implemented a battery powered 4-point measurement unit to interpret sensor readings.

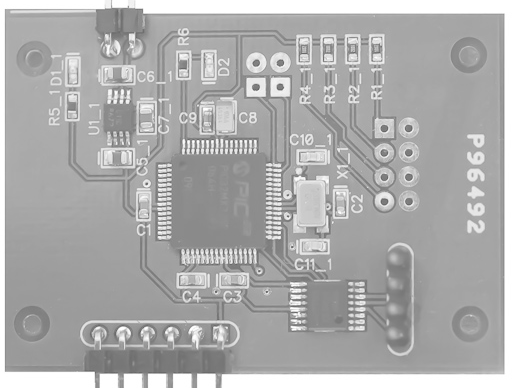

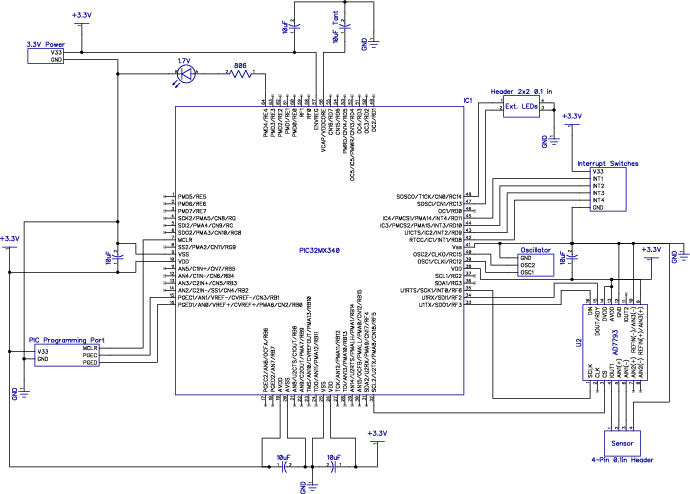

I created the measurement board leveraging an Analog Device AD7793 IC. This chip delivered most of the required functionality for a four point probe arrangement. When paired with a Microchip PIC32MX340 micro-controller using a serial peripheral interface (SPI), I was able to measure and interpret sensor data.

From the AD7793 data-sheet, I was able to write basic access routines in C to manage the IC from the micro-controller.

A showcase of the PCB, electrical schematic, and C firmware follows.

The circuit board was manufactured by Advanced Circuits, and hand assembled. SMT parts were re-flow soldered. Facilitating solder paste application, a stencil was obtained from Pololu Robotics & Electronics. After baking, solder bridges were removed using copper braid and a flat tipped soldering iron. Finally, through hole components were hand soldered.

Operation

C Firmware Source Files

/*******************************************************************************

* File: main.c

* Author: Steven Green

*

* Main routine for the AD7793 based demonstration board implementing a

* four point probe.

*

* This code runs on a PIC32MX340

******************************************************************************/

#include "AD7793.h"

// configuration bit settings, Fcy=40MHz, Fpb=20MHz

#pragma config POSCMOD = XT, FSOSCEN = OFF, FNOSC = PRI, ICESEL = ICS_PGx1

#pragma config FPLLIDIV = DIV_2, FPLLMUL = MUL_20, FPLLODIV = DIV_4

#pragma config FPBDIV = DIV_1, FWDTEN = OFF, CP = OFF, BWP = OFF

// Let compile time pre-processor calculate the PR1 (period)

// the frequency of the PIC32 microcontroller

// lower frequencies keep the current requirements lower

// the power supply generates 50mA this should be safely

// within the limits

#define SYS_FREQ (8000000L) // an initial divisor

#define PB_DIV 1

// prescaler used for the timer generating timer interrupts

#define PRESCALE 256

// desired number of measurements per second

#define TOGGLES_PER_SEC 8

// the number of clock ticks required to generate the desired number

// of interrupts (measurements) per second

#define T1_TICK (SYS_FREQ / PB_DIV / PRESCALE / TOGGLES_PER_SEC)

// 1 second ticks

#define T2_TICK (SYS_FREQ / PB_DIV)

// I/O definitions

#define LED _RE4 // LED bit, 1=on 0=off

#define LEDTRIS _TRISE4 // LED in/out control bit

// according to AD7793 specs the ID returned by the chip will

// be 0xXB. X can change but the B is constant. The following two

// masks are used to determine that the ID is in fact 0xXB

#define ID_AD7793 0x0000000B

#define ID_ANDMASK 0x0000000F

// define the number of averages to take in order to base the

// change in resistance

#define AVERAGES 10

// the sensor will trigger when the resistance drops to

// this percentage of the starting average value

#define PERCENTAGE 0.99

// TEST_POT_SENSOR sets the code

// ==1 expects the simulated sensor and blinks at a rate

// proportional to the resistance in the range

// ==0 expects an actual sensor and turns on an indicator

// when the sensor resistance drops to a predefined value

#define TEST_POT_SENSOR 0

int data; // ADC Valueint average;

// the average initial resistance measurementint trigger;

// the value to trigger an positive indicationint OK;

// flag to indicate the system is ready to collect data

void Delayms(unsigned t) {

T2CON = 0x8000; // enable TMR2, Tpb, 1:1

while (t--) {

// t x 1ms loop

TMR2 = 0;

while (TMR2 < T2_TICK / 1000)

;

} // Delayms

}

void Delaysec(unsigned t) {

LED = 1;

while (t--) {

Delayms(1000);

}

LED = 0;

}

main() // MAIN LOOP

{

OK = 0; // make sure the interrupt does not read a value

// until the AD7793 has not been configured

data = -1; // initialize data to -1

// the actual measurement will not be negative

int i, t;

int rData; // used to clear the read buffer

IEC0CLR = 0x03800000; // disable all interrupts

SPI1CON = 0; // stops and resets the SPI1.

rData = SPI1BUF; // clears the receive buffer

initAD7793();

// init the SPI for the AD7793

// setup a timer interrupt to trigger on a tick

// specified by T1_TICK this should correspond to

// TOGGLES_PER_SEC measurements per seconds

OpenTimer1(T1_ON | T1_SOURCE_INT | T1_PS_1_256, T1_TICK);

ConfigIntTimer1(T1_INT_ON | T1_INT_PRIOR_2);

INTEnableSystemMultiVectoredInt();

// init LED

LEDTRIS = 0; // LED pin output

LED = 0; // LED off

delay(); // wait probably not required

resetAD7793(); // send 32 high clocks to AD7793 to reset

// check the AD7793 ID

// check that ID is correct for chip

// bad SPI config will return wrong value

int isValid = verifyAD7793();

// main loop

if (isValid) // AD7793 OK setup the chip

{

setConfig(); // set AD7793 config register

setIO(); // set AD7793 IO register

runMode(); // put in run mode

calibrateInternalZero(); // perform internal zero calibration

calibrateInternalFullScale(); // perform internal high calibration

runMode(); // put back in run mode (performing conversions)

if (!errorStatus()) // check AD7793 error bit register

{

// wait 5 min before taking the average

Delaysec(60 * 5);

// set average and trigger values for the sensor

// positive indication

if (data == -1) {

// get an average resistance at the start

average = 0;

for (i = 0; i < AVERAGES; i++) {

average += readData();

}

average = average / AVERAGES;

trigger = average * PERCENTAGE;

}

OK = 1; // allow the interrupt to update the ADC reading

// main loop

while (1) {

if (TEST_POT_SENSOR == 1) {

// blink the LED at a rate proportional to the resistance range

LED = !LED;

// equation to set the blink rate

// specific to the test pot sensor

t = (((data / 16777216.0 * 3.3) - 0.099) / 0.051) * 95000 + 5000;

for (i = 0; i < t; i++)

;

// variable delay

} else {

// turn on the LED if the value drops below

// the lower resistance limit

if (data < trigger) {

LED = 1;

} else {

LED = 0;

}

}

}

} else {

// turn on the LED to indicate an error

LED = 1;

delay();

delay();

delay();

LED = 0;

}

} // main loop

while (1)

; // loop do nothing

// should not be here unless there is an error

} // MAIN LOOP

// timer interrupt

// read an ADC value periodically

void __ISR(_TIMER_1_VECTOR, ipl2) _TimerHandler() {

int i;

if (OK == 1) // the chip is configured properly

// if not OK do not read a value from the AD7793

{

data = readData(); // read an AD7793 value

}

mT1ClearIntFlag(); // clear the interrupt flag

}/*****************************************************************************

* File: AD7793.c

* Author: Steven Green

*

* Description: Source file for basic functionality provided for the AD7793

* chip.

*

* AD7793 Access Library

*****************************************************************************/

#define CS _RF5 // select line for Serial AD7793

#define TC _TRISF5 // tris control for AD7793

// peripheral configurations

#define SPI_CONF 0x8060 // SPI on, 8-bit master,CKE=0,CKP=1,SMP=1

#define SPI_BAUD 24 // clock divider Fpb/(2 * (SPI_BAUD+1))

// send one byte of data and receive one back at the same time

int writeSPI1(unsigned int i) {

while (!(SPI1STAT & 8))

;

SPI1BUF = i; // write to buffer for TX

while (!(SPI1STAT & 1))

;

return SPI1BUF; // read the received value

}

int readSPI1() { return SPI1BUF; }

void initAD7793(void) {

CS = 1; // de-select the Serial AD7793

TC = 0; // make CS pin output

SPI1BRG = SPI_BAUD; // use FPB/4 clock frequency

SPI1STATCLR = 0x40; // clear the Overflow

SPI1CON = SPI_CONF;

// SPI ON, 8 bits transfer, SMP=1, Master mode

// init the SPI1 peripheral

}

// initAD7793

// define CMD_READ_ID_REGISTER 0x60

#define ID_AD7793 0x0000000B

#define ID_ANDMASK 0x0000000F

void delay() {

int i;

for (i = 0; i < 100000; i++) {

} // delay

}

// reset the AD7793 to its default settings

// this is recommended for startup

int resetAD7793() {

// write 32 high bits to the AD7793

CS = 0; // select the AD9973

writeSPI1(0xFF);

writeSPI1(0xFF);

writeSPI1(0xFF);

writeSPI1(0xFF);

CS = 1; // unselect the AD9973

}

int verifyAD7793() {

int i;

CS = 0; // select the AD9973

i = writeSPI1(0x60); // next op read from the ID register

i = writeSPI1(0xFF); // read the 8bit register

CS = 1; // unselect the AD9973

return ((0x0F & i) == 0x0B);

}

// read the status register

int getStatus() {

int i;

CS = 0; // select the AD9973

i = writeSPI1(0x40); // next op read from the status register

i = writeSPI1(0xFF); // read 8bit status register

CS = 1; // unselect the AD9973

return (i & 0xFF);

}

// check if the error bit in the status register is set

int errorStatus() { return ((getStatus() & 0x40) != 0); }

// returns bits indicating the ADC channels being read

// there are three different registers

int getChannels() { return (getStatus() & 0x07); }

int setConfig() {

int i;

CS = 0; // select the AD9973

i = writeSPI1(0x10); // next op write to config register

i = writeSPI1(0x10); // write high 8 bits

i = writeSPI1(0x00); // write low 8 bits

CS = 1; // unselect the AD9973

return (i & 0xFF);

}

int runMode() {

int i;

CS = 0; // select the AD9973

i = writeSPI1(0x08);

i = writeSPI1(0x00);

i = writeSPI1(0x01);

CS = 1; // unselect the AD9973

return (i & 0xFF);

}

int setIO() {

int i;

CS = 0; // select the AD9973

i = writeSPI1(0x28);

i = writeSPI1(0x01); // both current sources pin 1, 10uA

CS = 1; // unselect the AD9973

return (i & 0xFF);

}

int readData() {

int i;

CS = 0; // select the AD9973

writeSPI1(0x58);

while (_RF2 != 1)

;

i = (writeSPI1(0xFF) << 16); // H

i |= (writeSPI1(0xFF) << 8); // M

i |= (writeSPI1(0xFF) << 0); // L

CS = 1; // unselect the AD9973

return i;

}

int calibrateInternalZero() {

int i;

CS = 0; // select the AD9973

writeSPI1(0x08);

while (_RF2 != 0)

;

writeSPI1(0x80); // H

writeSPI1(0x01); // L

CS = 1; // unselect the AD9973

return i;

}

int calibrateInternalFullScale() {

int i;

CS = 0; // select the AD9973

writeSPI1(0x08);

while (_RF2 != 0)

;

writeSPI1(0xA0); // H

writeSPI1(0x01); // L

CS = 1; // unselect the AD9973

return i;

}